1

/

of

6

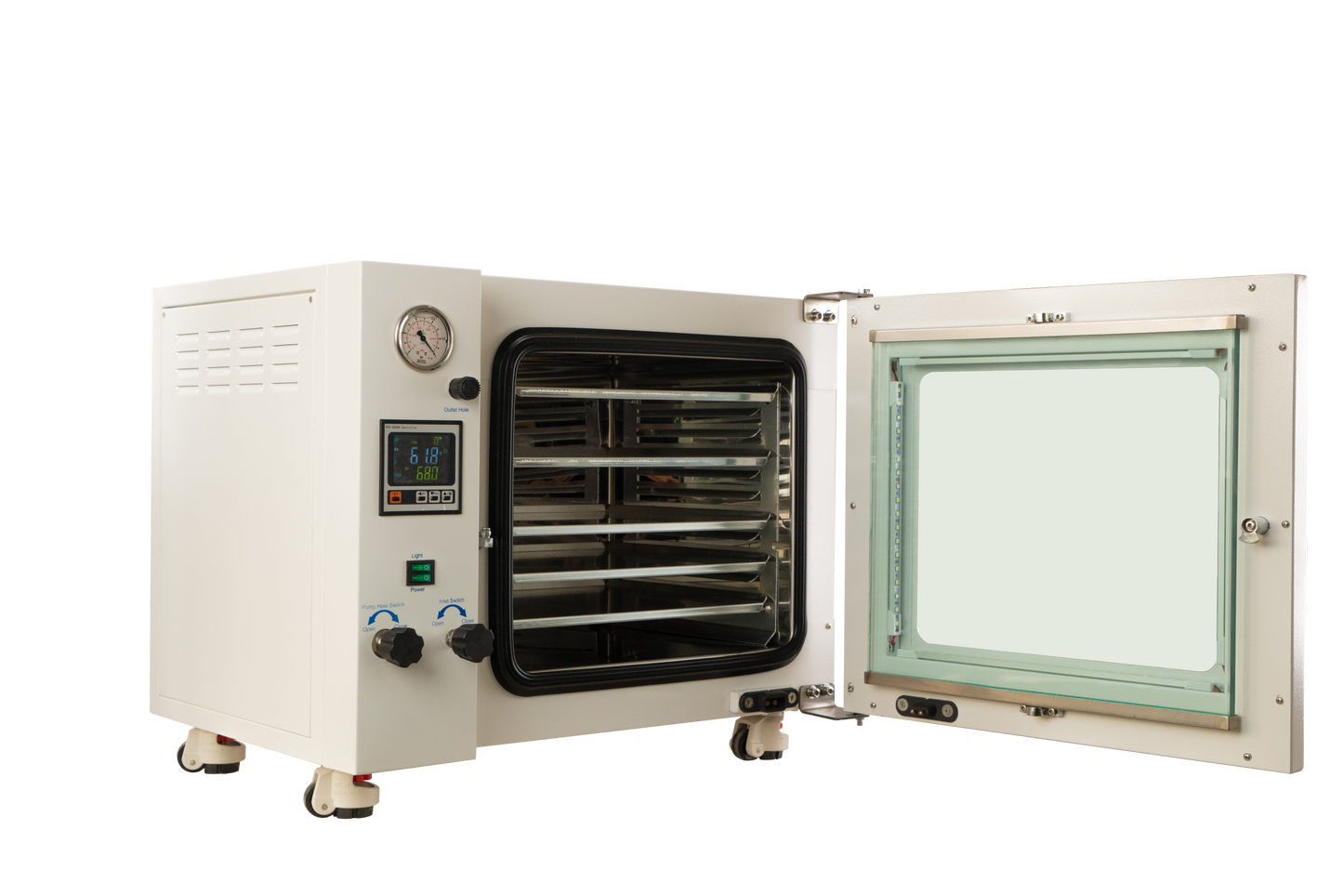

Vacuum Oven Lab Oven Laboratory Industrial Oven 110V 50/60Hz 850W 50L/1.9CF

Vacuum Oven Lab Oven Laboratory Industrial Oven 110V 50/60Hz 850W 50L/1.9CF

Regular price

$1,728.58 USD

Regular price

Sale price

$1,728.58 USD

Unit price

/

per

Specifications

| Place of Origin | China |

| Main Color | White |

| Main Material | Steel |

| Dangerous Goods | #dangerFlag# |

Dimensions & Weights

| Assembled Length (in.) | 28.30 |

| Assembled Width (in.) | 22.20 |

| Assembled Height (in.) | 22.80 |

| Weight (lbs) | 180.00 |

Product Features

- 5 - Sides heating distributes the heat uniformly under a vacuum.

- Temperature fluctuation reaches ±1°F.

- Dual layer tempered glass door with LED lights for clear observation.

- LCD display temperature PID controller with touch buttons.

- The working chamber is made up of SUS 304 Stainless steel and the outer shell is cold rolled steel.

- Ten removable aluminum shelves.

- ISO, CE certified.

Description

About this item

1. Five-sides heating, the heating element is located on the outer and rear walls of the chamber.

2. The PID temperature controller with timing and touch button, which is easy to operate.

3. LCD screen shows data which are easy to view.

4. The chamber is made of 304 stainless steel plate, and the body is made of high-quality cold-rolled steel.

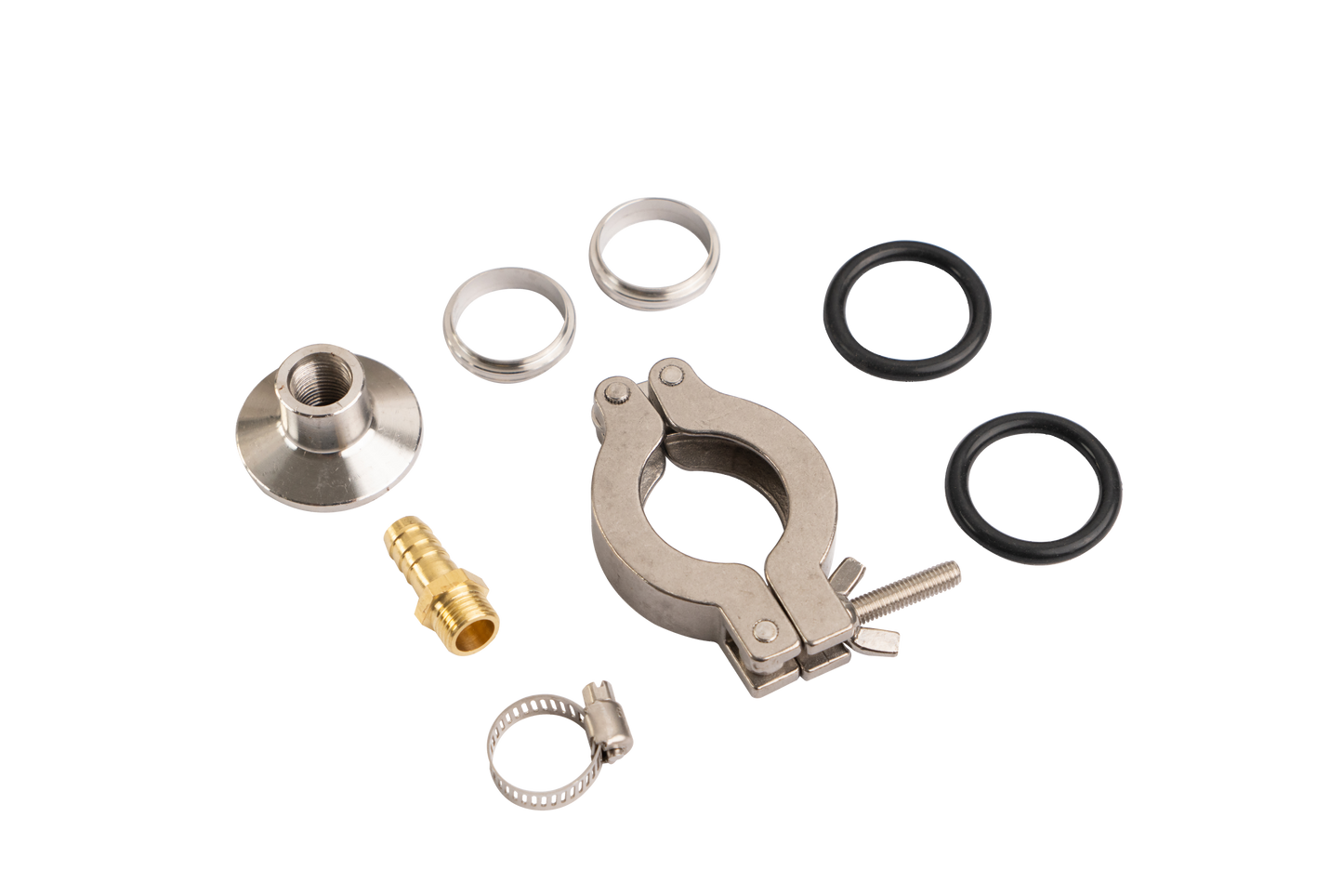

5. Oven is standard with KF25 to connect vacuum pump tube.

6. Inert gas inlet hole can be filled with nitrogen gas or other inert gas, if the experimental sample requires an inert environment.

7. Oil-filled mechanical pressure gauge is for more accurate vacuum readings.

8. Built-in advanced white LED lights are easy to observe samples.

Specific information

The oven body is made from high quality carbon steel stamping, the surface is electrostatic spraying and the chamber is stainless steel. Thermal insulation layer is made of high-quality silicate cotton, there is a high temperature resistant silicon rubber sealing ring between the chamber and the window, which ensure the sealed performance between the chamber and the door, increase substantially the vacuum degree in the oven.

Temperature control system use the PID temperature controller with touch button, do not need to adjust temperature control parameters, control precision and no overshoot. Temperature control system has the function of timing and over temperature protection, which improve the equipment safety.

1. Vacuum gauge

2. Air outlet hole

3. PID temperature controller

4. Power and LED light switch

5. Vacuum valve

6. Inert gas inlet valve

7. Observation window

8. Door handle

9. Leakage protection switch

10. Inert gas inlet hole

11. KF25 vacuum pump hole

12. Power socket

Technical Data

| Power Requirement | AC110V 60HZ |

| Power Consumptio | 850W |

| Temperature Range | RT~300℉ |

| Temperature Stability | ±1℉ |

| Display Resolution | 0.1 ℉ |

| Vacuum Range | 133Pa |

| Timing range | 1~9999min |

| Chamber Size | 16.34' x 14.57' x 13.78' |

| Oven Size | 28.3' x 22.2' x 22.8' |

| Volume | 50L/1.9CF |

| Shelves | 5pcs |

Product features

Product features

Materials and care

Materials and care

Merchandising tips

Merchandising tips

Share